What do we do?

SPG Fire & Security offers solutions that include all aspects of fire protection systems, from the design and planning to the providing of services after the installation

As a top-tier contractor of design and construction, SPG F&S can participate in all stages of the systems implementations process and can provide continual support to make sure that the fire protection systems operate at their maximum capabilities in case of fire.

Power plants, chemical processing facilities and heavy industry facilities are all environments that require many techniques and specific designs. Our designers here in SPG F&s employ many years of experience and the use of 3D modelling based in advanced systems to design plants and foresee all risks, and to navigate through the great deal of obstacles that can be found in most plants.

Project Engineering

Integrated Circuit

- Preliminary Study

- Project

- Development

- Introduction

We are a Team of Specialists in Fire Protection

- Knowledge of the various parts of a project.

- Ample and proven experience.

We use technology to achieve our goals

- Specific Software.

- Ideal/Optimal projects.

Supply of Specific Materials

Approved FM materials from the biggest brands: MUELLER, VICTAULIC, TYCO…

From automated sprinklers, stems… to OS&Y shut-off valves (flange or groove gate valves, sign posts for burying on the ground or placing on a wall, grooved butterfly valves with position indicator; also, sprinkler control systems, deluge and pre-action.)

INERGEN® Official Distributor

Up until the 1970s the most common gas-based extinguishing agent in deluge fire protection systems was carbon dioxide (CO2). CO2 presents a serious danger for human life, due to it being toxic in concentrations above 10%, and one needs concentrations above 30 % to put out a fire. With the introduction of Halons, and specifically of Halon 1301, the use of CO2 practically stopped, with the exception of some very specific applications.

Unfortunately, in the last few years it has been demonstrated that Halons greatly contribute to the destruction of the ozone layer. With the purpose of protecting said ozone layer by controlling the production of substances that degrade it, the Montreal Protocol entered into force on January 1st, 1989, effectively prohibiting the use of Halons in extinguishing systems, with the exception of some very specific applications. This prohibition has motivated the search for alternative extinguishing agents.

The use of alternative gases like industrial fluorinated gases (HFC’s, PFC’s and SF6’s) goes against the directives established in the Kyoto Protocol regarding climate change, which stipulates that there must be a reduction in the emission of these gases, which are responsible for the greenhouse effect or global warming.

The INERGEN® inert gas has become a 100% ecological alternative compatible with human life, for extinguishing systems based in gaseous agents.

- It does no harm to the ozone layer

-

It does not contribute to global warming

-

It has an atmospheric lifetime of zero

INERGEN® is a mixture of gases present in the air we breathe.

INERGEN® is a corrosive gas, non-toxic, that aids in the combustion process.

INERGEN® gives the brain the same ratio of oxygen present in normal air, without losing its effectiveness as an extinguishing agent.

Bearing in mind that INERGEN® is a clean agent that doesn’t damage objects and is safe for persons (it allows breathing), it is particularly adequate for the protection of areas where fire could cause great economic or human losses, such as:

-

Computer rooms

-

Transformer rooms

-

Archives

- Telecommunications centrals

- Labs

Installations

Detection Systems

Fire detection: thermal, heat detectors, smoke, flame, explosive and toxic atmospheres. Carbon monoxide (CO) detection equipment, with a two-stage alarm and an analogue indicator of CO concentration. Control and signaling equipment: systems for detecting conventional flammable and toxic gases, analogue and directional, with the possibility to activate previous alarms, ventilation equipment, extinguishing equipment and transmission to an alarm monitoring center

Water extinguishing systems

Water supply systems and fire protection pump rooms. (UNE, NFPA, FM, etc.)

Systems for the distribution of water via underground pipes and aerial pipes. Hydrants. Automated and manual monitors for water and/or foam. All types of sprinkler systems, for the protection of constructions, industrial buildings, warehouses, furnaces, etc. All in accordance to existing market regulations (UNE, NFPA, FM, etc.) Systems based in water pulverization for petrochemical, chemical and power plants. Fire Nozzles Systems, equipped in 25 mm. and 45 mm.

Extinguishing systems based in foam

Foam systems for flammable liquids. Fixed or Mobile. High, Medium and Low expansion. Proporcionadores de Espuma, Venturi-Presurizado, Presión Balanceada, Around-The-Pump, Venturi, etc.

Fire extinction via Chemical Powder

- Dry Chemical Powder Systems, Fixed, Semi-Fixed and Mobile; over-head, floor-nozzles, total deluge, etc.

- Portable extinguishers

Fire extinction via gaseous agents

Co2, inert gases, clean agents, local or total-application systems, designed according the norms for manipulation, transport and use in Spain (UNE) and Europe (CEN).

Maintenance

Maintenance of fire protection systems and equipment.

Fire protection facilities are of a vital importance for the security and protection of the public, as well as of material assets. The optimal use of the facilities is obtainable with the continuous and adequate maintenance performed by the Client, which is done according to the inspections established by all the different regulations.

SPG Fire & Security, recommends and offers the performance of these periodic inspections by specialized personnel, for making sure that the maintenance is done properly, and for detecting possible flaws and problems that might go unnoticed to the untrained eye.

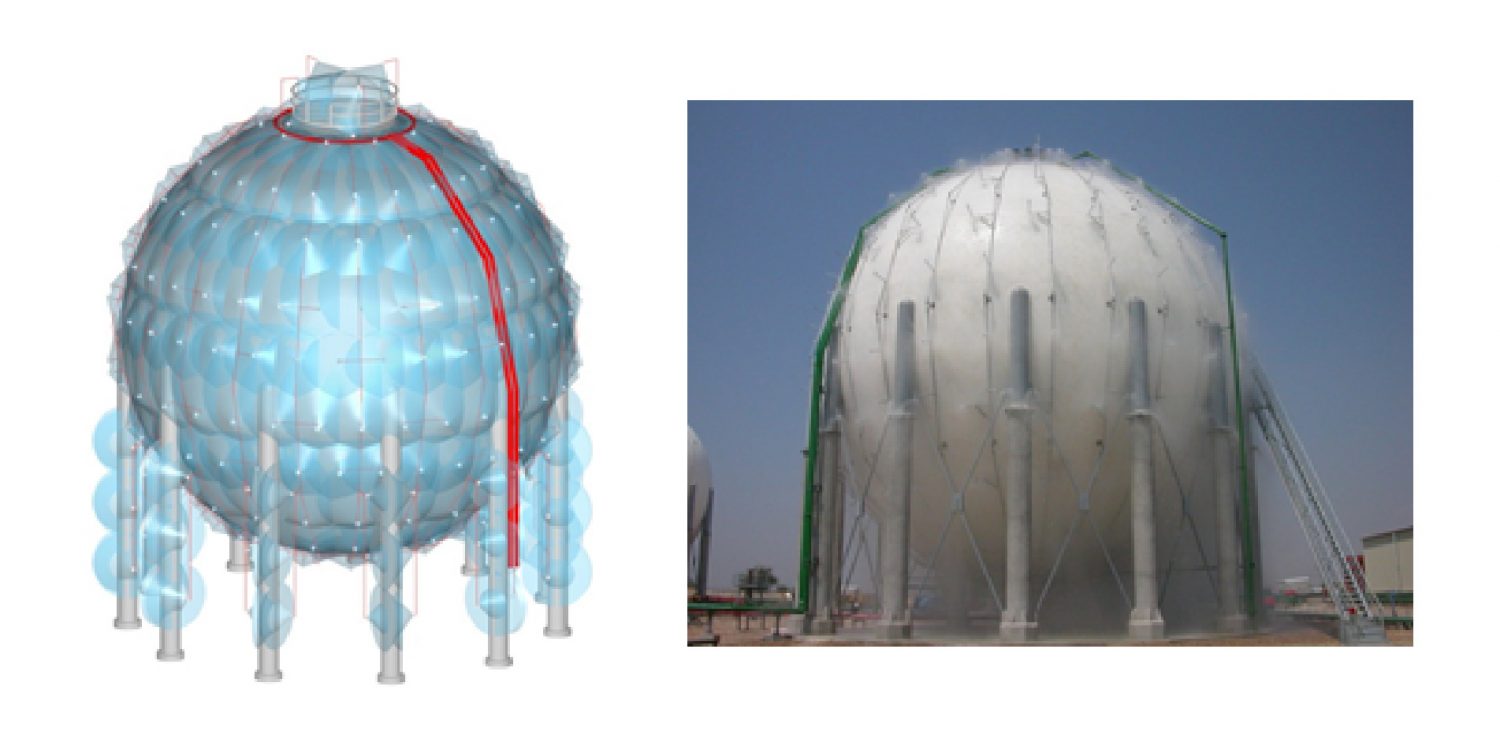

Self-directed Sphere Fire Protection System

Fire Protection via G.L.P. Spherical Containers

The spherical containers used to contain LPG’s represent a serious fire hazard, either by a leak or a fissure in the container itself, or by leaks or fires in the vicinity of the container, which can cause catastrophic incidents due to structural collapse of the damaged sphere. This is why said containers tend to feature protective measures against fire, basically consisting of refrigeration by water, according to international standards; in case of a dangerous increase in temperature on the walls or structural elements of the sphere, the sphere gets adequately refrigerated to protect its integrity from fire, thus avoiding disastrous accidents.

S.P.G. Sphere Fire Protection System

The Sphere Fire Protection System was developed in the 80’s by Salvador Pallarés (ETSIIB, Spain), an engineer specialized in fire protection with 35 years of experience, having first tried and tested its effectiveness. Since then, the system is endorsed by its 30 years of usage without problems in over 450 spherical containers installed in various countries around the world.

S.P.G. Fire & Security

As a company specialized in the installation of this system, S.L. has all the forging molds, application instructions, and design and assembly experience, which allows for the obtainment of a modular, straightforward, compact and secure system for fire protection in spherical containers used in LPG storage in chemical and petrochemical facilities.

Advantages of the S.P.G. Sphere Fire Protection System

- Installation is easy to disassemble

- Entirely pre-fabricated in our workshops.

- The installation is done after assembling the sphere, without damage to the paintwork or to any hole or opening.

- It can be done after the painting/lagging of the sphere and without a special scaffold, by using elements that retain inertia, placed in the platform above the assembly personnel.

Final advantages for the Client

- Since it can be entirely disassembled, it allows for periodic maintenance to the sphere after the mandatory period.

- The fire protection system can be disassembled, verified, cleansed, and stored; once having completed the maintenance of the sphere, it can be re-assembled, saving the client considerable resources.

- The option to use only 50% of the sphere’s surface reduces substantially the global water needs in the case of neighboring sphere clusters, which in turn reduces the problems with insufficient quantities in the pump systems.

3D Studio

More than fifteen years of experience in fire protection installations in the field of special hazards.

Pages of interest